40 years „Tools you can trust“

On course for expansion: Nachreiner GmbH celebrates anniversary

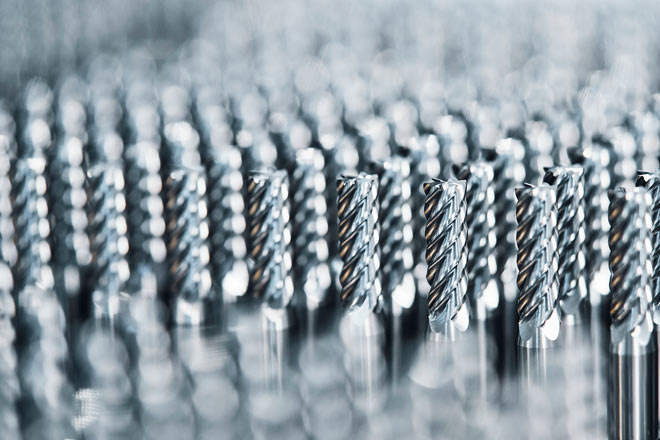

Tool solution provider combines sustainability with production efficiency

40 years as a competent solution provider for the metalworking industry – founded as a reliable, competent service provider for all aspects of metal-cutting tools, Nachreiner GmbH from Balingen-Weilstetten has today developed into a globally sought-after, sustainable manufacturer of high-performance tools and tool concepts that are always setting new standards in metal-cutting. With its large vertical range of manufacture, state-of-the-art production technologies, high innovative strength, flexibility and wide-ranging service and support services in both, the classic and the digital areas, the competent team around the management of Marianne and Siegfried Nachreiner and daughter Sandra Hallas is ideally positioned for current and future market challenges.

The first Nachreiner office in 1981 in Balingen-Streichen.

When Marianne and Siegfried Nachreiner founded “Nachreiner Spanabhebende Werkzeuge” in 1981 in a small office in a residential building in Balingen-Streichen, they had no idea what a successful path their company would take in the decades to come.

The slogan “tools you can trust” quickly got around in the industry: thanks to the high tool quality and expertise, the young company quickly gained the status of a competent and reliable partner for the metalworking industry. In particular, manufacturers in the key industries of southern Germany, such as automotive and mechanical engineering, quickly had Nachreiner in the Zollernalbkreis district on their list as a solution provider.

From 1989 onwards, the portfolio was expanded to include solid carbide tools and, in the course of cooperation with an Italian partner, a separate Nachreiner tool product range was launched.

When the second generation of the family joined the management with daughter Sandra Hallas in 2000 and the company was renamed Nachreiner GmbH in 2002, the future course was set for the solidly growing company, which was also reflected in the steadily increasing number of employees.

Siegfried Nachreiner, founder and managing director of Nachreiner GmbH: “A lot has changed over the decades: New materials, new machining processes, increased demands on precision, product quality, but also energy and resource efficiency continuously present new challenges to our customers in the metalworking and metal processing industry – and thus also to us as a partner and engineering service provider in the tool sector. In order to always have our finger on the pulse of time and market requirements, to implement our own ideas and to continuously invest in securing and developing our location, we have recently set the course for our own production.”

Working closely together, the Hallas & Nachreiner families always run the company true to the motto “Precision means leaving nothing to chance”.

Sustainable action with a large vertical range of manufacture

Considerable investments in the past as well as currently ensure Nachreiner’s solid growth and the tools to always keep pace with the constantly increasing challenges of the market: In 2007, Nachreiner GmbH invested in the first production facility for premium standard tools – a joint venture in Bavaria, and in 2009 in the second joint venture in Zell am Hamersbach/Black Forest for solid carbide reamers and special tools. A special milestone in the company’s history was the opening of the completely new main production facility with connected customer experience and logistics centre at the headquarters in Balingen-Weilstetten in 2013, in the course of the expansion phase that continues to this day. In 2018, the production, storage and office capacities were significantly expanded.

The headquarters in Balingen-Weilstetten has several production halls, a logistics centre, offices and a customer experience centre.

The Nachreiner canteen is a place of relaxation for the staff and the management.

At its headquarters, Nachreiner combines resource-conserving, sustainable action with economical, profitable tool production and is thus constantly pushing ahead with its efforts to combine climate and environmental protection with efficient corporate goals. To overcome this balancing act, Nachreiner involves all employees, technology suppliers and customers, for example, in order to reduce the company’s ecological footprint.

Due to the high vertical range of manufacture, the tool specialist has the entire value chain and the product quality for the production of the standard programme, as well as for the so-called “quick fixes” in the special tool area under its own control: In-house tool design, cleaning procedures of the blanks before grinding, temperature-stabilised production units, state-of-the-art technology for edge preparation and optimisation of the micro-geometry, state-of-the-art grinding, measuring and automation technology are fixed parameters of the tool production designed for sustainability, efficiency and quality. With the integration of premium coating expertise from CemeCon, Nachreiner is able to equip even the cutting tools with the best hard material coatings that are currently available.

Hall 2 of the Nachreiner production facility in Balingen-Weilstetten, completed in 2020.

Siegfried Nachreiner, Managing Director of Nachreiner GmbH: “Our precision tools solve the most demanding machining tasks worldwide and set standards in the machining of metal, non-ferrous metals, plastics and composite materials. We always offer a broad portfolio of new, market-driven tool solutions for a wide range of applications. Recent highlights include, for example, new tools for machining operations in the steel sector, special solutions for tool and mould making and for non-ferrous metal machining, for example in aerospace or e-mobility. With our tool solutions, we secure a clear technological lead for ourselves and our customers.”

Thanks to an optimised storage and logistics concept, for example with a large semi-finished product warehouse including prefabricated blanks, deliveries at short notice are also possible within a very short time. This ensures calculable production reliability for the industry even in times of high tool demand.

Modern tooling solutions from Nachreiner are used in the key industries of the German economy.

The company’s own sales staff support the area of southern Germany, and a close-knit network of national sales partners covers the rest of the Federal Republic. The company’s strong growth, which was further accelerated in 2020 by the new production facilities, is also reflected in the growing export business, which plays a key role in Nachreiner’s strategic market positioning. Nachreiner has sales representatives and customers in over 60 countries, and the company is constantly expanding its global commitment.

Successful combination of traditional and digital service

In addition to the personal contact between manufacturer and customer through competent and individual advice, Nachreiner is consistently expanding its sales and information offering in the digital sector. Here, too, Nachreiner is relying on forward-looking developments, for example in the area of web shops or helpful web apps, in order to inform the user quickly and comprehensively and to guide him to the required tool or its data in a targeted manner with just a few clicks. Siegfried Nachreiner: “Getting information about the company, products and services in the shortest possible time, finding and ordering the right tool with just a few clicks – our high-performance website is a highly regarded digital business card”.

The management is proud of its team, which is constantly growing: Highly motivated and competent in all areas, they keep the wheels turning. The low staff turnover keeps profound know-how in the company, and Nachreiner customers work with the same contact persons for many years. The statement of the management is therefore clear: “As a medium-sized, family-run company, we stand by our customers as a source of impetus and ideas, want to grow with them and support them in mastering future machining challenges. A constantly increasing number of satisfied customers shows us that we are on the right way. The goal is to continue to grow solidly in the national segment and at the same time to further expand international market shares.”