About NACHREINER

About NACHREINER

In 1981, Siegfried and Marianne Nachreiner founded the company NACHREINER – SPANABHEBENDE WERKZEUGE. Since its foundation, speed, quality, flexibility and extensive stock-keeping have been the philosophy of the family company. In 2002 the company was renamed into a limited liability company and has been certified according to DIN EN ISO 9001.

The aim is to be able to serve customers optimally and comprehensively, always with optimised precision tools and a larger stock. As today’s standard tools often do not adequately meet the required demands, the company was additionally expanded by a production facility in Balingen and in the Black Forest. This has enabled us to meet the ever-increasing machining requirements. With state-of-the-art equipment, we are problem solvers for our customers worldwide.

The guiding principle “Precision means leaving nothing to chance” underlines the high demands the company places on its products. We always want to stay one step ahead of the market demands.

Precision is nature’s gift to technology – and the heartbeat of our company

Precision is nature’s gift to technology – and the heartbeat of our company

40 years of Nachreiner – the headquarters in Balingen-Weilstetten

Our headquarters in Balingen-Weilstetten has several production halls, coating facilities, a logistics centre, offices and a customer experience centre. In addition, Nachreiner GmbH owns another production site in the Black Forest. The management consists of the founder Siegfried Nachreiner and the daughter Sandra Hallas. Together, the two generations always manage Nachreiner GmbH true to the motto “Precision means leaving nothing to chance”.

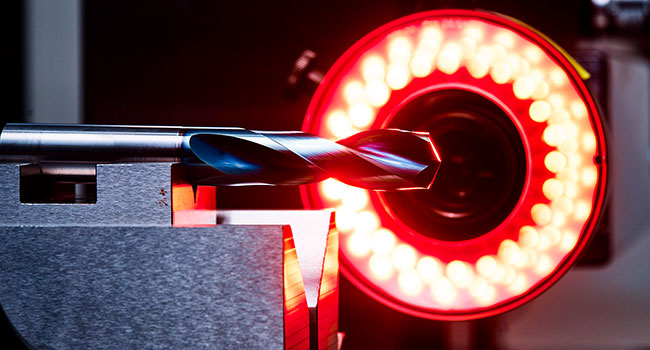

Nachreiner cutting tools – manufacturing quality

As a manufacturer and supplier of metal-cutting tools, we rely on the highest manufacturing quality “Made in Germany”. We use state-of-the-art machines from Walter, Anca, Rollomatic, CemeCon and Co. to manufacture Nachreiner premium tools. Ultra-fine grain carbide, temperature-stabilised & sustainable production and state-of-the-art technologies for edge preparation are further important components of our tool quality.

At our main production site in Balingen-Weilstetten, we produce various tools for machining technology, such as milling tools and drilling tools according to common DIN and Isonorm standards made of solid carbide.

In-house coatings with CemeCon HiPIMS process

Our product quality is completely in our own hands – thanks to the integration of the new CemeCon HiPIMS coating systems, we can equip our tools with the best hard material coatings for cutting tools. In addition, the HiPIMS process is extremely future-proof, so that we can directly and flexibly adapt the tool coatings optimally to changing market challenges. This ensures our customers an absolute technological advantage.

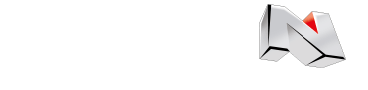

Premium product quality thanks to special quality assurance

“Tools you can trust” – this is not just our slogan but a quality promise to our customers. In order to be able to guarantee you Nachreiner premium quality, we not only need highly trained employees, modern machines and coatings, but also sophisticated quality assurance methods. We also rely on the best testing equipment, such as 3D surface measuring devices from Alicona.

Our quality management is DIN EN ISO 9001 certified.

Experience cutting technology up close in the customer experience centre

We always offer our customers the opportunity to experience new tools live and up close. In our customer experience centre, our tool technicians show you the optimal use of milling tools, drilling tools, threading tools, etc., for example via imachining from SolidCAM. Because our goal is always to offer you the perfect conditions for working with Nachreiner cutting tools.

Interested? Then why not arrange a meeting right away.

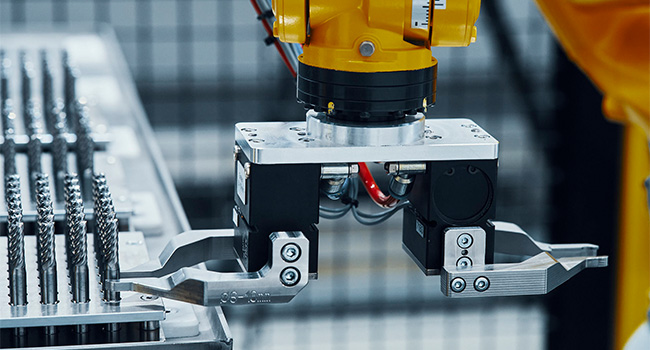

For a good working relationship – Our service for you

Our products are not the only evidence of premium quality! As a reliable manufacturer, supplier and solution partner for cutting tools, we also offer you excellent service. Whether with our cutting data calculator for optimal tool use, a live chat for fast & uncomplicated support, online appointment calendars or our well-trained employees – we are always there for you and will make working with us as pleasant as possible.

40 years of Nachreiner – the headquarters in Balingen-Weilstetten

Our headquarters in Balingen-Weilstetten has several production halls, coating facilities, a logistics centre, offices and a customer experience centre. In addition, Nachreiner GmbH owns another production site in the Black Forest. The management consists of the founder Siegfried Nachreiner and the daughter Sandra Hallas. Together, the two generations always manage Nachreiner GmbH true to the motto “Precision means leaving nothing to chance”.

Nachreiner cutting tools – manufacturing quality

As a manufacturer and supplier of metal-cutting tools, we rely on the highest manufacturing quality “Made in Germany”. We use state-of-the-art machines from Walter, Anca, Rollomatic, CemeCon and Co. to manufacture Nachreiner premium tools. Ultra-fine grain carbide, temperature-stabilised & sustainable production and state-of-the-art technologies for edge preparation are further important components of our tool quality.

At our main production site in Balingen-Weilstetten, we produce various tools for machining technology, such as milling tools and drilling tools according to common DIN and Isonorm standards made of solid carbide.

In-house coatings with CemeCon HiPIMS process

Our product quality is completely in our own hands – thanks to the integration of the new CemeCon HiPIMS coating systems, we can equip our tools with the best hard material coatings for cutting tools. In addition, the HiPIMS process is extremely future-proof, so that we can directly and flexibly adapt the tool coatings optimally to changing market challenges. This ensures our customers an absolute technological advantage.

Premium product quality thanks to special quality assurance

“Tools you can trust” – this is not just our slogan but a quality promise to our customers. In order to be able to guarantee you Nachreiner premium quality, we not only need highly trained employees, modern machines and coatings, but also sophisticated quality assurance methods. We also rely on the best testing equipment, such as 3D surface measuring devices from Alicona.

Our quality management is DIN EN ISO 9001 certified.

Experience cutting technology up close in the customer experience centre

We always offer our customers the opportunity to experience new tools live and up close. In our customer experience centre, our tool technicians show you the optimal use of milling tools, drilling tools, threading tools, etc., for example via imachining from SolidCAM. Because our goal is always to offer you the perfect conditions for working with Nachreiner cutting tools.

Interested? Then why not arrange a meeting right away.

For a good working relationship – Our service for you

Our products are not the only evidence of premium quality! As a reliable manufacturer, supplier and solution partner for cutting tools, we also offer you excellent service. Whether with our cutting data calculator for optimal tool use, a live chat for fast & uncomplicated support, online appointment calendars or our well-trained employees – we are always there for you and will make working with us as pleasant as possible.

More information about NACHREINER

More information about NACHREINER